creep test ss304 high temperature|stainless steel creep fatigue : exporters The creep–fatigue interaction behavior of materials is frequently simulated in the laboratory by high-temperature low-cycle fatigue (HTLCF) tests with incorporation of hold time . Atenção 2ª via de boleto. 2ª via de boleto. FAQ - Covid-19 e Gripe. Download. TUTORIAIS PARA NOVO PORTAL EMPRESAS. Visualizar vídeos. Novo manual do Portal empresa. Download. TUTORIAL - FATURAMENTO NOVO PORTAL. . Sobre o GNDI O Grupo; Saúde Planos de saúde Pessoa Jurídica; Planos de saúde Pessoa Fisíca .

{plog:ftitle_list}

Akinator peut lire dans ton esprit et te dire à qui tu penses. P.

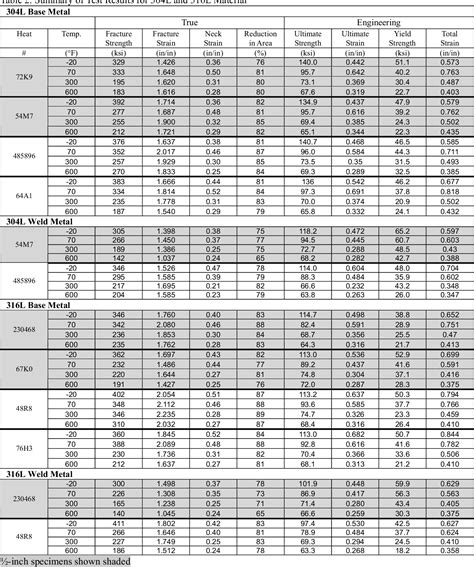

type 304 stress test results

The elevated-temperature creep behavior of Type 304 stainless steel is examined in terms of the measured effective and internal stresses. Results show that the mean ef-fective s t r e s s is .

type 304 strain test

Multiaxial creep-fatigue test results are summarized for type 304 stainless steel. Uniaxial and nonproportional cyclic tests with low strain rates are conducted. The capacities of . The creep–fatigue interaction behavior of materials is frequently simulated in the laboratory by high-temperature low-cycle fatigue (HTLCF) tests with incorporation of hold time .

high-temperature strength properties should be given priority; creep or creep-rupture (sometimes called stress- rupture). If the component is small and/or the tolerances .2. Creep Fatigue Test of Dissimilar Welded Joints of SUPER304H™ To examine the basic fatigue properties of dissimilar welded joints of SUPER304H™ at high temperature, the creep fatigue . Stress levels for creep testing were established as a percentage of yield stress. The results indicate that at lowered temperatures and lower stress levels, AISI 304 stainless .

Specimens of 304 stainless steel were subjected to uniaxial tension creep tests at high temperature. The high temperature creep tests were conducted in air using a constant stress creep machine.

A numerical integration of creep relaxation curves from strain-controlled fatigue tests with hold times introduced at peak strain is performed to sum creep damage by the linear life fraction .The elevated-temperature creep behavior of Type 304 stainless steel is examined in terms of the measured effective and internal stresses. Results show that the mean effective stress is .

type 304 stainless stress test

type 304 stainless stress

dbt condom burst tester

Determination of the elastic and plastic properties of SS304 at high temperature by application of inverse FEA on small punch creep test results محل انتشار: کنفرانس دو سالانه بین المللی مکانیک جامدات تجربی

The MPC Omega material coefficien ts specifically for material type SS304 . has been utilized to assess the creep deformation of high-temperature components. . experimental creep test data .

Determination of the Elastic and Plastic Properties of SS304 at High Temperature by Application of Inverse FEA on Small Punch Creep Test Results February 2014 Conference: International Conference . The creep behaviour in vacuum of type 304 stainless steel of intercept grain size 12 ± 3 μm has been investigated for stresses up to 13 MN/m2 (2 × 10-4 G), temperatures between 823 and 1023 K .

The elevated-temperature creep behavior of Type 304 stainless steel is examined in terms of the measured effective and internal stresses. Results show that the mean effective stress is related to the applied stress by a power law of the form σ* = α(σ)β, where the constants α and β are functions of temperature. The dependence of creep rate on applied stress follows a power . The creep response of an AISI 304L steel with a high proportion of low-Σ grain boundaries was investigated by means of constant-load creep tests at 853 and 923 K. Microstructural studies revealed an extended precipitation of intragranular carbides, given sufficiently long times of exposure to creep.

Download scientific diagram | Temperature-dependent SS304 stress-strain data and the corresponding bilinear fit. from publication: In-situ Creep Testing Capability Development for Advanced Test . The effect of tensile hold time on the value of N f of 304 SS at 550 °C [15], [16] and 538 °C [5], [7], [8], [17] can be found in Fig. 4.When the temperature is 550 °C, the tensile hold time on the creep fatigue endurance can be neglected by comparing with the continuous cycling when the hold time is lower than 1.0 min.After hold time of 1.0 min, the number of cycles to .Creep is the slow, time-dependent strain that occurs in a material under a constant strees (or load) at high temperature. High temperature is a relative term, dependent on the materials being .

Length of time that the alloy is subjected to a given temperature. Just to name a few potential factors that might affect the performance of a steel alloy being exposed to high temperature applications. For example, say that you had a container made of plain steel that you were passing through a process where the temperature would reach 1,000 . For materials that cannot be expressed in variable-separated form, a combined function called θ projection [31], [32], [33] has been developed for long-term creep as: (4) ε c = θ 1 (1 − e − θ 3 t) + θ 2 (e θ 4 t − 1) where the first term corresponds to rate-decrease effect (such as in primary creep) and the second term corresponds to rate-increase effect (such as in . HIGH-TEMPERATURE CHARACTERISTICS OF STAINLESS STEEL A DESIGNERS’ HANDBOOK SERIES NO 9004 Produced by AMERICAN IRON AND STEEL INSTITUTE Distributed by NICKEL . short-time tensile test is higher than the creep or stress-rupture strength. temperatures above 900°F (482°C), becomes a major factor in determining

Download scientific diagram | Temperature-dependent Young's modulus for SS304. 26,33,36,38 from publication: In-situ Creep Testing Capability Development for Advanced Test Reactor | Creep is the . The creep life prediction of austenitic heat-resistant steel is necessary to guarantee the safe operation of the high-temperature components in thermal power plants. This work presents a machine learning model that can be applied to predict the creep life of austenitic steels, offering a novel method and approach for such predictions. In this paper, creep life . The present study explores the creep and high-temperature tensile performance of the P92/304L dissimilar weld joint. The gas tungsten arc welding (GTAW) technique was used to prepare the .

high temperature winding wire that is serviceable up to 225℃. The canning enclosure was fabricated with SS304 alloy. The winding former was fabricated out of Teflon. The probe and test specimen SS304 were fastened with Teflon clamps and sand witched with stack of SS shim foils placed between probe

1. Introduction. Residual/ remnant life prediction, as a major element of prognosis and health management (PHM) of components and equipment subjected to high temperatures and stresses in industry, has been a major concern of researchers in recent years [1].At present, predicting the creep life of present and new generation creep-resistant materials which are .

Acquisition of 304SS Creep Law in a High-Temperature Water Environment. 2.1. Experimental Equipment and Method. Slow strain rate stress corrosion tester is adopted in creep test of 304 stainless steel. According to the temperature range of the safety end outlet of the primary pressure vessel in the nuclear reactor . The AISI 310 stainless steel, 310 SS for short, is commonly used for high temperature applications, displaying an austenitic (γ) matrix with some residual δ-ferrite and primary M 23 C 6 carbides. During service at intermediate and high temperatures, there is formation of sigma (σ) phase and secondary M 23 C 6 carbides. Precipitation of σ phase has .

Test specimens for this study were prepared from an as received commercial thick walled pipe made of 304 LN grade stainless steel. The chemical composition in weight percentage is shown in Table 1.The material was initially provided with a solution annealing heat treatment at 980 °C for 8 h and cooled in furnace.Room and high temperature (600 °C) tensile tests on as .In a creep test, a constant. | Creep, High Temperature and Tensile | ResearchGate, the professional network for scientists. Figure 1-1 - uploaded by Bong Goo Kim. . (SS304) found in the .Due to the loading and to the temperature, these devices are submitted to creep under complex atmosphere with low oxygen partial pressure content. Unusual damages and high creep strain rates have been reported on components made of 310S Stainless Steel. Therefore, the mechanical behavior at high temperature of this alloy was investigated. Many data

This expansion coefficient not only varies between steel grades, it also increases slightly with temperature. Grade 304 has a coefficient of 17.2 x 10-6 /°C over the temperature range 0 to 100°C but increases above this temperature. The effect of thermal expansion is most noticeable where components are restrained, as the expansion results in buckling and bending.Fig. 3. (a) Compressive stress – strain behavior during the creep test at 769 MPa (= 1.6 σYS) for a holding period of 3600 s at 23 C. (b) Creep strain increment with time during the entire holding period. (c) Creep strain observed after one-hour creep test at different stress levels with respect to the yield strength. As a nickel-based alloy, GH4169 has the properties of excellent corrosion resistance, high temperature oxidation resistance and high creep resistance. In this paper, the compression creep behaviors of cylinder entangled wire materials (CEWMs) made from metal wires (GH4169 nickel-based alloy, 304 stainless steel) were investigated at elevated . This study reports the significant ambient temperature creep plasticity at stresses below the conventional 0.2% plastic strain off-set yield stress. This is partially due to the relatively high strain-rate sensitivity of 304 stainless steel. Cold-working significantly increases the creep resistance. Descriptive equations that predict low-stress creep plasticity, which are somewhat .

Characteristics in High Temperature – Creep & Rupture Curve A : constant load test Curve B : constant strain test Fig. 1.3.3.1 Creep and Rupture Curve of Metals (1) Allowable stress value after long term operation at elevated temperature (2) Creep-Rupture Stress: See API 530 Fired Heater Tube Calculation (use the allowable stresses of Annex E) /

stainless steel creep fatigue

high temperature stainless steel specifications

Damnation. Uma saga épica sobre a história secreta do coração da América na década de 1930, Damnation centra-se no conflito mítico e na luta sangrenta entre a riqueza e os .

creep test ss304 high temperature|stainless steel creep fatigue